Applications of CNC machining & 3D printing, sheet metal processing in the consumer goods industry:

1. CNC machining: CNC machining is used in the consumer goods industry to produce high-precision components for various products such as appliances, electronics, and furniture. Some examples of CNC machined components in the consumer goods industry include:

· Appliance components: CNC machines are used to produce components for appliances such as handles, knobs, and control panels.

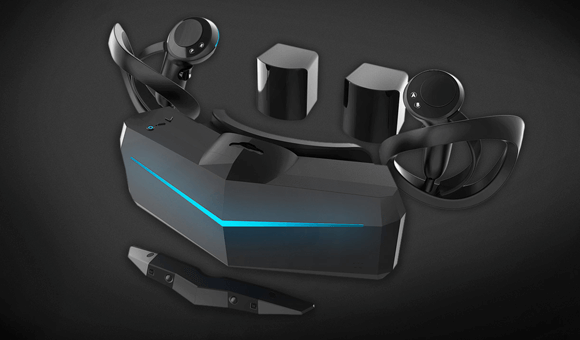

· Electronics components: CNC machines are used to produce components for electronics such as cases, brackets, and connectors.

· Furniture components: CNC machines are used to produce components for furniture such as legs, frames, and hardware.

2. 3D printing: 3D printing is a rapidly growing technology in the consumer goods industry and is used for a variety of applications, including:

· Prototyping: 3D printing is used to create prototypes of new consumer products, which can be tested and refined before being produced using traditional manufacturing methods.

· Customization: 3D printing is used to produce customized products such as phone cases, jewelry, and toys.

· Tooling: 3D printing is used to produce molds, jigs, and fixtures for use in traditional manufacturing processes.

3. Sheet metal processing: Sheet metal processing is used in the consumer goods industry for the production of components such as:

· Appliance components: Sheet metal processing is used to produce components for appliances such as housings, panels, and doors.

· Electronics components: Sheet metal processing is used to produce components for electronics such as cases, brackets, and frames.

· Furniture components: Sheet metal processing is used to produce components for furniture such as frames, supports, and hardware.

Consumer electronics HOTFrom prototype to production to homes around the world

Consumer electronics HOTFrom prototype to production to homes around the world Automotive HOTDrive product development and speed up innovation

Automotive HOTDrive product development and speed up innovation Medical NEWAccelerating new product introduction for the medical industry

Medical NEWAccelerating new product introduction for the medical industry Robotics & automation NEWBuild the most complex automated systems with ease

Robotics & automation NEWBuild the most complex automated systems with ease Aerospace & aviation

Aerospace & aviation Industrial machineryPower your machines with cutting-edge technologies

Industrial machineryPower your machines with cutting-edge technologies