Introduction

When comparing the properties of different materials, charts are an intuitive and effective tool. Through these charts, we can clearly observe the advantages and disadvantages of various materials in key performance indicators. This article will analyze the comparisons of common materials (such as metals, plastics, and composites) in terms of physical properties, mechanical strength, corrosion resistance, weight, and cost, assisting you in better understanding and selecting the materials that meet your requirements. You can first get familiar with the English names of relevant materials and then click on the charts to enlarge and view them.

1. Materials Involved in the Material Property Comparison Charts

in English and Chinese

Three-dimensional slicing of material properties space: modular-strength-density slicing

2. Young's Modulus - Density

Young’s modulus, also known as the tensile modulus, is one of the most common types of elastic modulus. It measures the stiffness of an isotropic elastic body. The elastic modulus encompasses Young’s modulus, along with the bulk modulus and shear modulus.

3. Strength - Density

Strength refers to the ability of a part to resist fracture or excessive residual deformation beyond the allowable limit when subjected to a load. In other words, strength is a crucial indicator for measuring the load - bearing capacity (i.e., the ability to resist failure) of a part itself.

4. Young's Modulus - Strength

5. Specific Modulus - Specific Strength

The specific modulus is the elastic modulus per unit density. It is an important indicator of a material's load - bearing capacity. The larger the specific modulus, the greater the rigidity of the part, and it is also known as the "specific stiffness."

The specific strength is the ratio of a material's strength to its apparent density. A higher specific strength indicates that less material mass is required to achieve a certain strength. High - quality structural materials should have a relatively high specific strength to meet strength requirements with a smaller cross - section and significantly reduce the self - weight of the structure.

6. Fracture Toughness - Young's Modulus

Fracture toughness is the resistance value shown by a material when, in the presence of cracks or crack - like defects in a specimen or component, it does not experience rapid fracture starting from these defects as the load increases (i.e., when so - called unstable fracture occurs). Fracture toughness characterizes a material's ability to resist crack propagation and is a quantitative indicator for measuring the toughness of a material.

7. Fracture Toughness - Strength

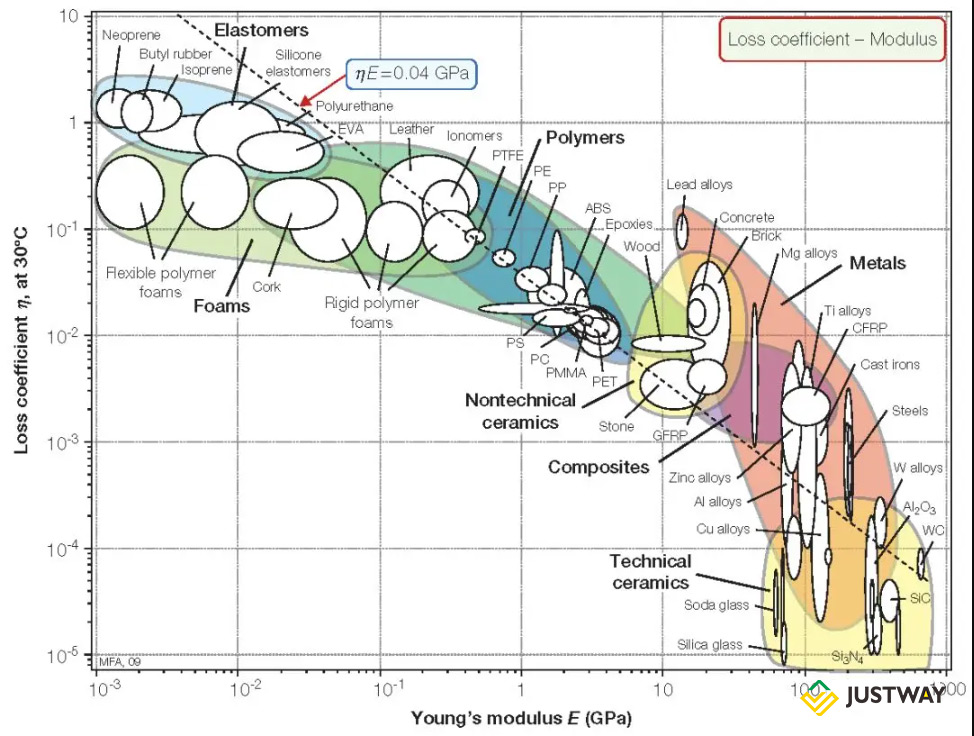

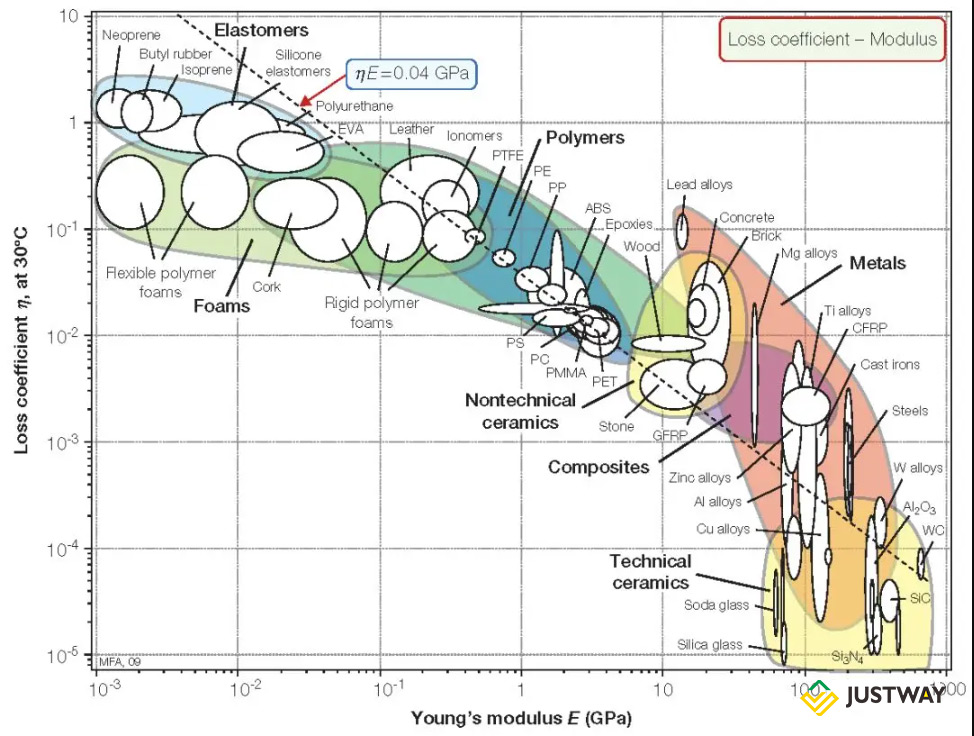

8. Loss Coefficient - Young's Modulus

Material damping, also known as internal friction in materials science, refers to the phenomenon of mechanical vibration energy loss caused by internal factors such as the mutual friction of material grains when the material vibrates. The damping of a material is usually represented by the loss coefficient or damping ratio. The damping characteristics of a material are related to its internal structure and are significantly affected by the surrounding environment, such as magnetic fields and radiation, and are closely related to temperature and vibration frequency.

9. Thermal Conductivity - Electrical Resistivity

Thermal conductivity refers to the amount of heat transferred per unit area under steady - state heat transfer conditions. It only applies to the heat transfer mode of conduction. When there are other heat transfer modes, such as radiation, convection, and mass transfer, the related property is usually called the apparent thermal conductivity, explicit thermal conductivity, or effective thermal conductivity.

Electrical resistivity is the ratio of the product of a material's resistance and cross - sectional area to its length and is a physical parameter for measuring the electrical conductivity of a material. It is not only related to the type of material but also to external factors such as temperature, pressure, and magnetic fields.

10. Thermal Conductivity - Thermal Diffusivity

Thermal diffusivity measures the rate at which a temperature disturbance at one point in an object is transferred to another point. It represents the ability of an object to achieve a uniform temperature during heating or cooling. The larger the thermal diffusivity of an object, the stronger the ability of heat to diffuse from the surface to the interior or from the interior to the surface. The deeper the temperature change can reach, and the faster the temperature difference at different depths can be eliminated. Conversely, if the thermal diffusivity is smaller.

11. Thermal Expansion - Thermal Conductivity

The coefficient of linear expansion refers to the rate of change of an object's linear dimensions with changes in external temperature or pressure, indicating the degree of expansion or contraction of the material.

12. Thermal Expansion - Young's Modulus

13. Wear Rate Constant - Hardness

The wear rate constant refers to the amount of wear of a material under a certain pressure.

Hardness refers to the ability of a material to locally resist the indentation of a hard object into its surface.

Generally, the fatigue - wear resistance of a material increases with the increase of surface hardness. However, once the surface hardness exceeds a certain value, the situation is reversed.

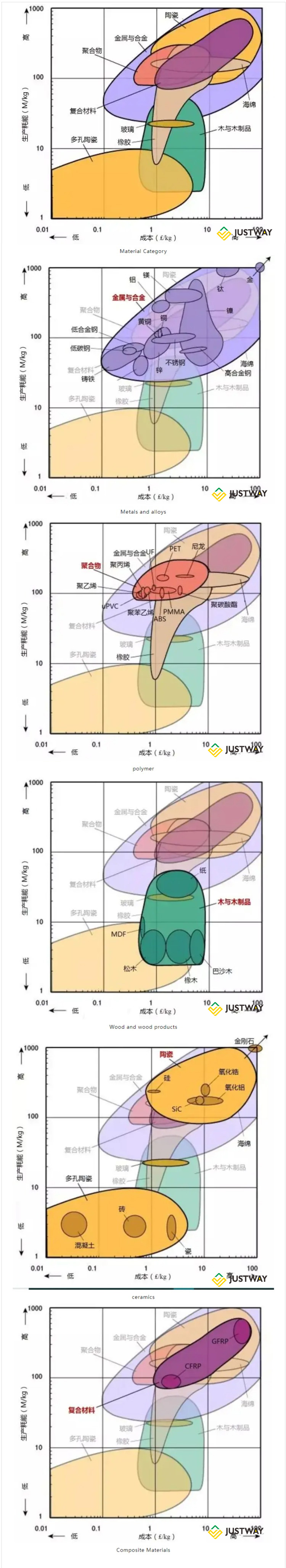

14. Young's Modulus - Relative Cost per Unit Volume

15. Strength - Relative Cost per Unit Volume

16. Thermal Conductivity - Strength

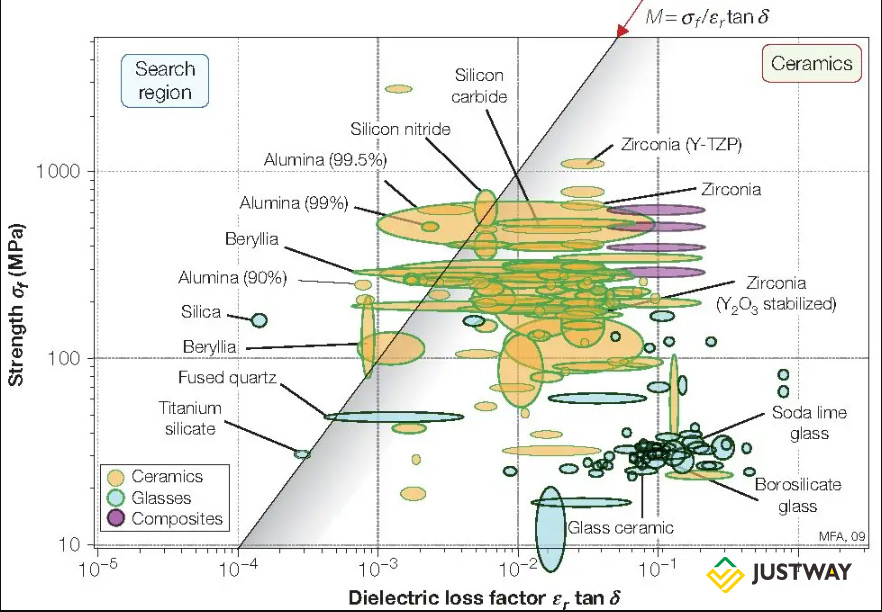

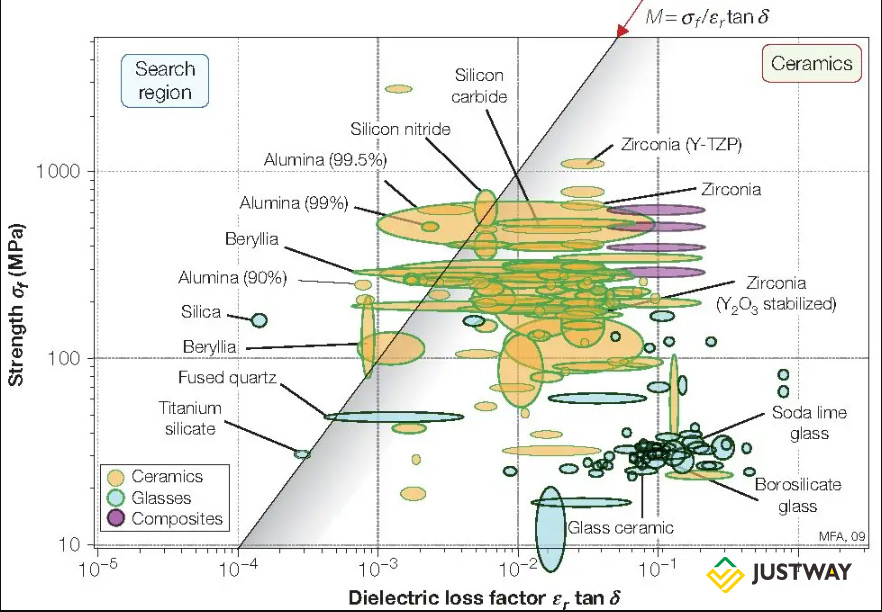

17. Strength - Dielectric Loss Factor

Dielectric loss refers to the phenomenon in which a dielectric material generates heat due to the consumption of part of the electrical energy in an alternating electric field. The smaller the dielectric loss, the better the quality and insulation performance of the insulating material.

18. Strength - Dielectric Loss Factor (Polymers)

19. Strength - Dielectric Loss Factor (Ceramics)

20. Electrical Resistivity - Young's Modulus

21. Thermal Expansion - Maximum Service Temperature

22. Young's Modulus - Embodied Energy

Embodied energy refers to the total amount of energy consumed during the production process of a certain material.

23. Strength - Embodied Energy

24. Tactile Properties of Materials (Soft - Hard/Warm - Cold)

The tactile properties of materials refer to the sensations of softness/hardness and warmth/coolness felt when the human body comes into contact with the materials.

25. Pitch and Tone Color Characteristics of Materials

The tone color characteristics of materials refer to the sound frequency (tone color) formed when the materials vibrate.

26. Material Price (Unit Weight or Unit Volume)

27. Specific Heat Capacity - Density

The specific heat capacity is the amount of heat required to raise the temperature of a certain amount of homogeneous material by 1K without phase change and chemical change. The larger the specific heat capacity, the stronger the heat absorption or heat dissipation ability of the object.

28. Specific Heat Capacity - Price

29. Strength - Elongation

The elongation refers to the change in the length direction of a material before fracture.

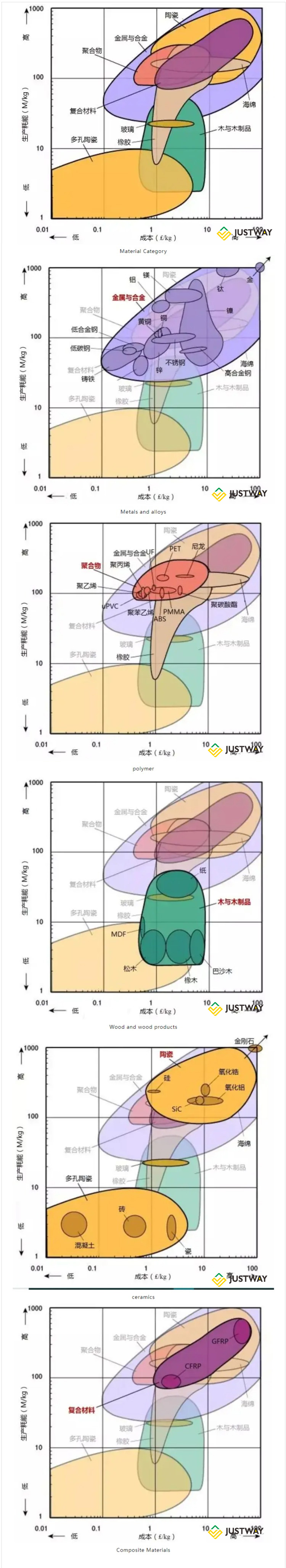

Material Category;Metals and alloys;Metals and alloys;polymer;ceramics;Wood and wood products;Composite Materials

30. Electrical Resistivity - Relative Cost

Major Material Categories and Included Materials

Material Category;Metals and alloys;polymer;Wood and wood products;ceramics;Composite Materials

31. Recycle Fraction - Relative Cost

Major Material Categories and Included Materials

32. Embodied Energy - Relative Cost

Major Material Categories and Included Materials

Material Category;Metals and alloys;polymer;Wood Products;ceramics;Composite Materials

3D Printing

3D Printing

Automotive

Automotive

Electrical

Electrical

Energy and Power

Energy and Power

Industrial Design

Industrial Design

Just for Fun

Just for Fun

Medical

Medical

Robotics

Robotics

Tech

Tech

Tools

Tools