-

Capabilities

- Processes Available

- CNC Machining Service

- CNC Milling

- CNC Turning

- Electrical Discharge Machining

- Metal

- All metal

- Aluminum

- Stainless steel

- Brass

- Copper

- Titanium

- Mild steel

- Alloy steel

- Tool steel

- Spring steel

- Processes Available

- Sheet Metal Fabrication Service

- Laser Cutting

- Bending

- Welding

- Plastic

- All plastic

- PMMA (Acrylic)

- Carbon Fiber

- Processes Available

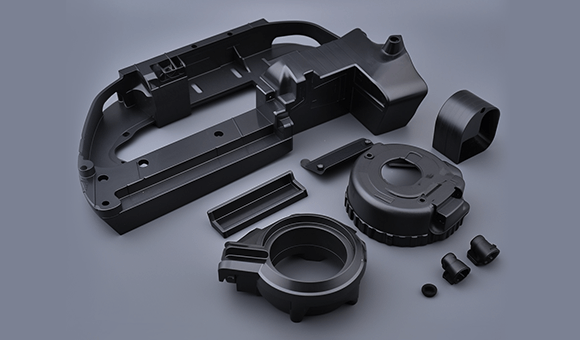

- Injection Molding Service

- Injection Molding

- Overmolding

- Insert Molding

- Processes Available

-

Urethane Casting

(Vacuum Casting)

-

Industries

-

Consumer electronics HOTFrom prototype to production to homes around the world

Consumer electronics HOTFrom prototype to production to homes around the world -

Automotive HOTDrive product development and speed up innovation

Automotive HOTDrive product development and speed up innovation -

Medical NEWAccelerating new product introduction for the medical industry

Medical NEWAccelerating new product introduction for the medical industry -

Robotics NEWAccelerating new product introduction for the robotics industry

Robotics NEWAccelerating new product introduction for the robotics industry -

Aerospace NEWGo from development to launch faster

Aerospace NEWGo from development to launch faster -

Industrial machineryPower your machines with cutting-edge technologies

Industrial machineryPower your machines with cutting-edge technologies

-

- Resources

-

Company

- Feedback

- 3D models

Your Cart

Show up to the latest 200 orders

Data loading, please wait ...

Your cart is currently empty.

Get a quote

Subtotal

US $0

V0 Member 0% OFF

-US $0

Taxes ,coupon and reward points calculated in checkout

We accept all major credit cards

Total

$0

View Cart